One of our volunteers in the sewing group needed an extension table for her sewing machine. We were asked to help. And so we constructed one in the time honoured fashion of making it up as we went along. Contemporary jargon would call this rapid prototyping. Our first picture shows the project well under way to give you all a fair idea of what’s being talked about. The following photos are stages in building the subframe.

Apart from puzzling what the table might look like we also need to work out what material we might use. We have a large stock of wooden bed slats and floorboard offcuts. And it is this stock that we’ll use. However it needs cutting to size. The main machine used is our Lumber Jack table saw. These are the strips of wood cut for the frame.

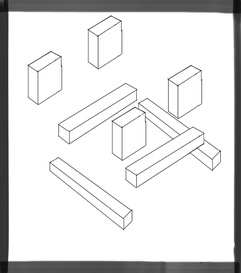

Looking at this frame picture one might reasonably wonder how the notches are cut. It is possible to cut such notches in a piece of timber. However we are after a speedy result so the shape is fabricated with everything superglued. Superglue because it sets almost instantaneously. At a later stage, if all goes well, mechanical fixings can be inserted. This diagram might help understand.

The deck/table is fabricated in a similar way. The rectangular slot could be cut but making it from 3 pieces is way quicker.

Sometimes we imagine beautifully cut joints and elaborate constructions but, as said, this needed to be quick and simple. In essence the whole job was glued together with superglue. In many ways all jobs can be considered as prototypes for the next job, in this instance if this works there’ll be no need to revisit the project. As we proceeded we check with our sewing group colleague if, what we were proposing, was to their liking. Working in such a manner makes on the spot consultation easy and, if you like, rather democratic. Nothing is so precious that it can’t be changed or even abandoned. Earlier we talked about making it up as we went along which may seem impressive but, stored away in our memories are similar projects. If you like our minds contain a lexicon of making. And so when presented with such a challenge we already have a fair idea of how to proceed. We had the material, we have the tools so we’re already well on the way.