Georgian Kitchen Table – Some further Thoughts

- Share

- Share

- Share

- Share

Georgian Kitchen Table - Some Further Thoughts

By total happenstance another kitchen drop leaf table has been donated to us. These two tables are at least 150 years apart in their age and yet one realises that there are enormous similarities. The newer table is, we guess from the mid 1980’s. The needs of folk in their kitchens has not really changed that much. The key differences between these tables is that the younger one is mass produced, using laminated ply and demountable joints – probably to facilitate flat packing for long distance transport.

Underneath we can see different methods of supporting the drop leaf. And we notice that the younger table has ‘sticks’ to keep the leaves up rather than the more elaborately shaped swinging brackets. Many of the differences that we’re looking at can be attributed to an expansion of international trade, an economy in production cost, use of composite materials and the necessity for flat packing to make long distance transport to market easier.

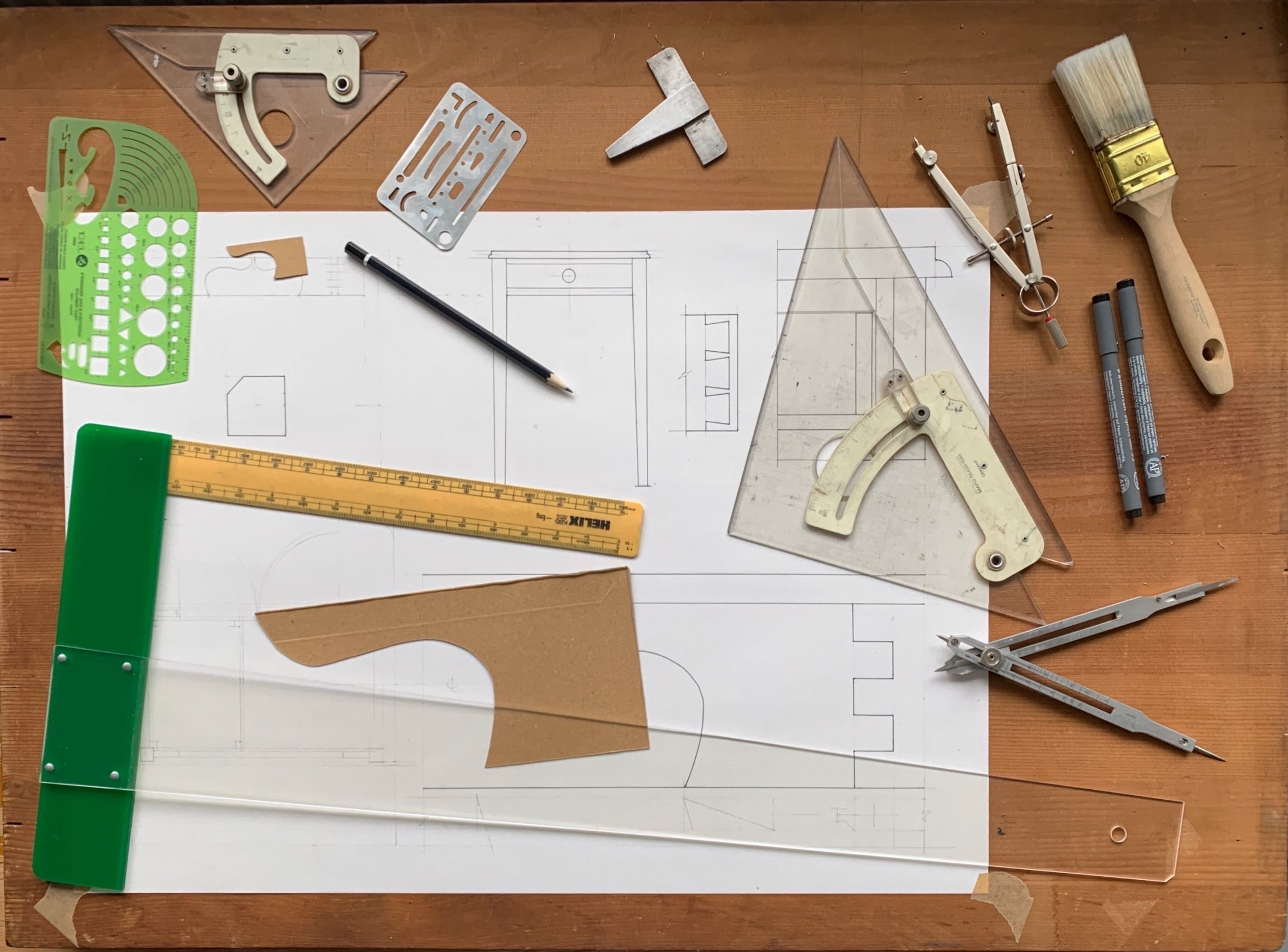

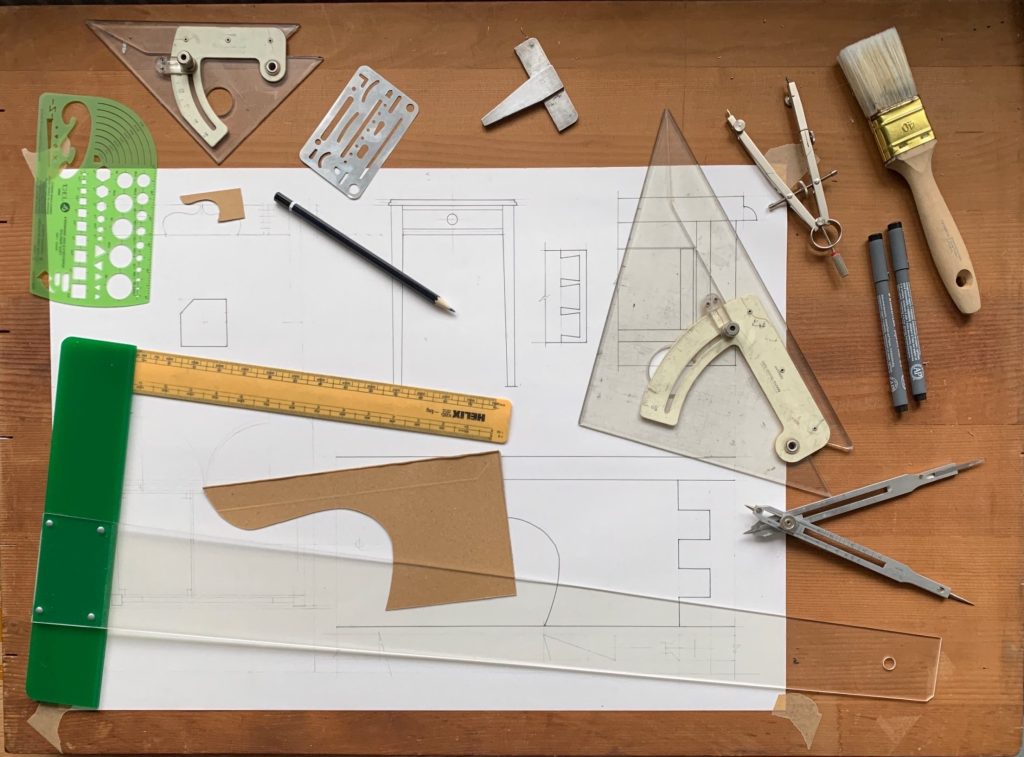

As mentioned in the previous post the table is also being measured so that a technical drawing can be produced. Here is a shot of my drawing board with drawing in progress. You’ll realise that, in this instance, the drawing method is very traditional. My guess is that, in principle these techniques have been used for 100’s of years. Some of the instruments are plastic but the techniques that they are being used for are deeply traditional.

This is one of the fold out drop leaf supports. At least two questions arise from this detail. One is how was this marked out and cut in the workshop and the other how might this be measured and drawn? The answer to both lies in the use of templates. Originally the workshop would have drawn and cut a template which would have been used to mark out and cut the part. Essentially I’m doing a reverse engineering exercise. I traced the bracket on stiff card which was used as a template for the drawing. For the smaller scale template (to the top left in the drawing board picture) I took some key co-ordinating measurements and drew the curves freehand.

Which is all rather a long way from Computer Aided Design used for contemporary must have fitted kitchens.

On Other Matter

For us Fixing and Looking at Heritage items undoubtedly holds a big interest. However the workshop has many requirements that need looking after, for example there’s tool maintenance and improving machinery to mention but two. So today we’ve added an auxillary fence to our table saw’s mitre gauge. It’s the piece of wood that you see. This is used when we’re cross cutting material to size. And because of its added length it improves stability to the pieces cut and therefore improves the angular accuracy of cut.

We write rarely, but only the best content.

Please check your email for a confirmation email.

Only once you've confirmed your email will you be subscribed to our newsletter.

Your items have been added to your basket.